PRODUCT

صفحة رئيسية>منتجات>

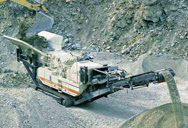

iron ore primary crushing

The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. 2022年1月1日 The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that Comminution and classification technologies of iron ore2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments. The primary objective of Iron Ore Processing: From Extraction to Manufacturing

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation The primary crushers take blasted, run-of-mine, or run-of-quarry feed up to 1500 mm and produce a product ranging in size from -300 mm for conveyor transport, or -200 mm for Primary Crusher Optimisation for Improved ComminutionThis paper briefly reviews the background of mobile primary crushers and their current main areas of application. The benefits of applying mobile primary crushing and belt Application of Mobile Primary Crushing and Belt Conveying

A Mine-to-Crusher Model to Minimize Costs at a

2022年8月18日 The primary crushers are four mobile roller crushers (PF 200–9500) with the feed size between 0.80 m to 1.20 m and a maximum product size of 0.35 m; the crushed ore is transported through a system The broken stone is dumped into a primary crusher where the large rock fragments are broken into smaller sizes. Crushing to the proper size usually occurs in stages because Primary Crusher - an overview ScienceDirect Topics2015年12月23日 In in-pit crushing, the primary function of a crusher is to provide a smaller uniform product size for each of transport by the conveying system. Minimum power consumption in part of a good design. For their Primary Crusher Selection Design - 911 Metallurgist

Primary Crushing SpringerLink

Primary crushing brings run-of-mine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below “Dry”

- الشركة المصنعة للمعدات تعدين الفحم

- دعم آلة تكسير الحجر في ولاية كارناتاكا 2018

- 92 كرات وسائط طحن الألومينا عالية القوة لمصانع السيراميك

- ماشین آلات و آسیاب

- نعمة الاسمنت البناء طحن الإيدز

- الصين مواصفات مخروط محطم

- ماشین آلات سنگ معدن در ایالات متحده استفاده می شود

- ديمبسي مصنع صخرة سحق

- التعدين الكرة الصغيرة مطحنة تايوان

- الأردن كسارة الرمال محجر الحجر

- الهيماتيت كسارة التعدين خام

- تاجر معدات الفحم التعدين إيران طحن مطحنة الصين

- جهاز لتطبيق الحصى على القوباء المنطقية

- الرمل الاصطناعي صنع آلات من عمان

- مقالات عن تعدين الذهب في العالم

- فيات اليس 64 الات ثقيلة

- تكلفة رأس المال في عملية تعدين رمل السيليكا

- گوجه فرنگی چرخ

- مطحنة عمودية بريدجبورت مستعملة للبيع في فلوريدا

- الشركة المصنعة محطم في الإمارات العربية المتحدة